Exploring the Longevity of American-Made Wellhead Systems

In the energy industry, the durability of infrastructure is of importance. Wellhead systems and components in oil and gas extraction operations ensure the smooth and secure execution of drilling activities. This article delves into examining the longevity of wellhead systems crafted in the United States, shedding light on why these systems are constructed to withstand the test of time and establish a standard for excellence and dependability in the market.

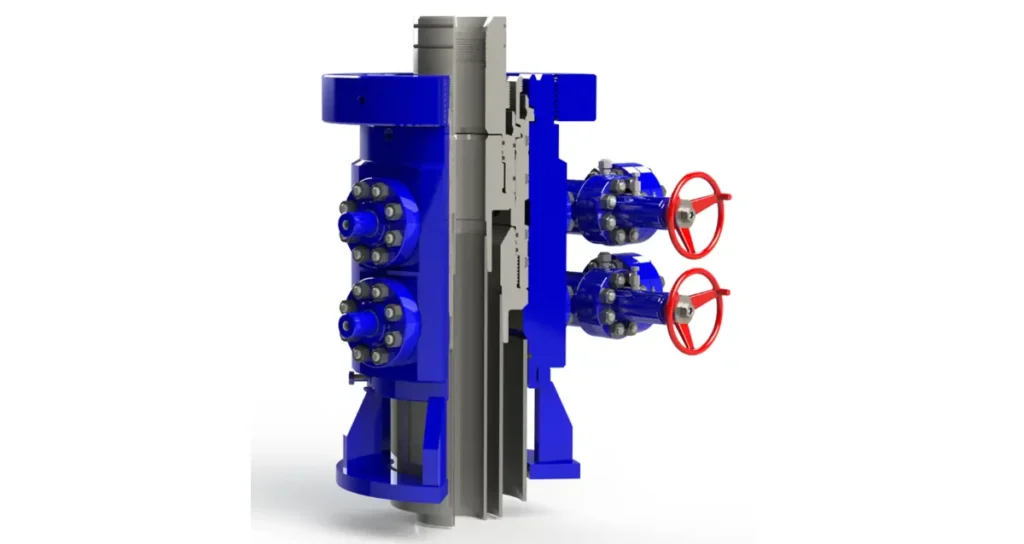

Insight into Wellhead Systems

A wellhead system acts as a link between surface drilling and production equipment and the intricate underground network. Its purpose is to provide an interface containing pressure for drilling and production equipment. The main functions of a wellhead include sealing off oil or gas wells, creating support points for casing strings, and providing a mechanism to connect blowout preventers during drilling operations.

The Significance of ‘Made in the USA’

‘Made in the USA’ goes beyond being a label—it embodies a dedication to quality that reverberates on a global scale. Wellhead systems produced in America benefit from manufacturing standards, innovative engineering practices, and top-notch materials. These elements collectively contribute to creating products known for their durability and performance.

Materials Selection and Production Techniques

Choosing the materials plays a role in determining how long wellhead systems will last. American manufacturers commonly use top-quality steel and various alloys specifically engineered to withstand the conditions found in oil and gas sites, including pressures and corrosive environments. The manufacturing methods involve testing and quality checks to ensure that each wellhead system is constructed to endure the conditions it will face.

Innovative Design Approaches

Innovation is an aspect of manufacturing that is also important for wellhead systems. Engineers continually look for ways to enhance performance and durability through improved designs. This involves incorporating technologies like sealing mechanisms and materials that resist corrosion, which can significantly prolong the lifespan of these systems.

Adherence to Regulations and Standards

The United States has regulations governing oil and gas equipment manufacturing, making it one of the most stringent regulatory environments globally. Compliance with these standards guarantees that every wellhead system meets and often surpasses safety and performance requirements. This commitment to compliance plays a role in ensuring the longevity and dependability of wellhead systems.

Ensuring Quality through Checks

Maintaining quality control is an aspect of producing wellhead systems in the United States. Each component undergoes a series of tests to identify any flaws or abnormalities. Manufacturers utilize cutting-edge testing methods, such as X-ray and magnetic particle inspection, to guarantee that the final product is devoid of imperfections.

Field Performance and Dependability

The accurate measure of a wellhead system lies in its performance out in the field. Wellhead systems manufactured in America have a proven track record of performance, often surpassing their counterparts in terms of reliability and longevity. This can be attributed to their design, high-quality materials, and meticulous attention to detail throughout manufacturing.

Customer Service

In addition to the product itself, American manufacturers offer customer assistance and service. This includes guidance on installation, regular maintenance support, and repair services—all essential for ensuring the system’s longevity. Swift and dependable customer service ensures that any issues are promptly resolved, further enhancing the system’s lifespan.

Conclusion

Wellhead systems produced in the United States are a testament to engineering prowess and manufacturing excellence. With a dedication to quality, innovation, and strict adherence to industry standards, these systems guarantee durability and reliability.

Opting for American-made wellhead systems from OTSO Energy Solutions promises value, safety, and long-term efficiency for industries relying on extraction processes. Thanks to their enduring quality and reliable legacy, wellhead systems in the USA are expected to remain crucial as the energy sector changes.

FURHTER READING