The Push for Silicon-Graphene Batteries by US Military

A recent US military investment in next-generation battery technology has provided a $15 million contract for NanoGraf to invest in development of silicon-oxide-graphene (SOG) batteries. The purpose it seems is to enhance the feature of power storage related to portable military equipment: small tactical universal batteries (STUBs), which are used to back up devices such as radios, GPS units, and laser systems. Why is the U.S. military investing in this technology, and what makes silicon-graphene batteries so promising?

The Military’s Battery Dilemma

Modern soldiers carry comprehensive equipment – about 100 pounds of it for each man. That encompasses as much as 20 pounds of batteries. The basis for this demand has to do directly with the range of battery-driven devices that soldiers rely upon for communication, navigation, and targeting.

Moving forward with lighter, yet longer-duration batteries allows soldiers to either minimize their battery load or extend their missions. That meets one strategic objective of the decision: to cut back on China, supplying over 80 percent of the world’s lithium-ion batteries. The military wants a made-in-the-U.S. solution for reliable and advanced power storage.

Enter Silicon-Graphene (SOG) Batteries

NanoGraf’s SOG batteries integrate a silicon oxide anode supported by a graphene scaffold. This combination offers distinct advantages over conventional lithium-ion batteries, including:

- Increased Energy Density: NanoGraf claims their SOG batteries provide a 15% longer runtime and are 15% lighter than comparable models.

- Extended Range and Playback: The SOG battery cells reportedly deliver up to 20% more range and 50% longer playback time.

- Faster Charging: Silicon-based batteries charge up to 10 times faster than traditional lithium-ion batteries.

These improvements, though they may seem modest, are critical in military scenarios where extra power or quicker recharges can influence mission success.

How SOG Batteries Work: The Role of Silicon and Graphene

The mechanics behind SOG batteries lie in their unique use of silicon oxide and graphene:

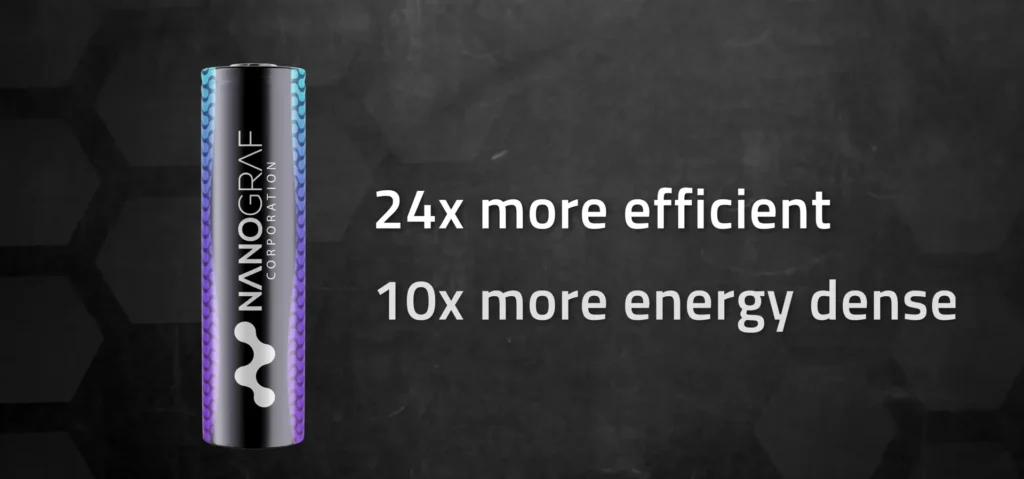

- Silicon’s Lithium Storage Capacity: Unlike graphite, which has long been used as an anode material in lithium-ion batteries, silicon atoms can store more lithium ions, offering up to 24 times the storage capacity. This significantly increases the battery’s energy density.

- Challenges of Silicon Anodes: Silicon’s storage advantage comes with downsides. The material tends to swell and contract as it absorbs and releases lithium ions, which can cause the anode to degrade over time. The solution? A graphene scaffold.

- Graphene’s Conductive Properties: Known as a “wonder material,” graphene is one of the most conductive materials available and also remarkably strong. Graphene’s structure provides a conductive, durable scaffold that supports silicon particles, helping mitigate issues with swelling while maintaining a lightweight design.

Cost and Manufacturing Challenges

Graphene still has too many advantages, yet it remains an expensive and impractical material. To mass produce high-quality graphene for electronic uses, pricier manufacturing processes remain in place, which are enormous limitations. What NanoGraf has done is put their graphene scaffold into a production line battery, bypassing pricey silicon manufacturing processes such as vapor deposition. Scaling this method may help to bring the price down with accessibility.

Military-Driven Innovation for Civilian Use

Early investment by the military in SOG technology creates funding for innovation that can eventually make its way back to benefit the public. The history of military technological advances is one of eventual domino effects on everyday consumer products, from GPS technology to canned food. If NanoGraf’s technology proves successful for military applications, silicon-graphene batteries could likely find their way into consumer electronics or electric vehicles.

Expansion Plans and Future Prospects

In addition to the DOD contract, NanoGraf recently received a share of $60 million from the Department of Energy for its fabrication of one of the largest silicon battery factories in the world, Flint, Michigan. It is supposed to produce about 2,500 tons of silicon anodes yearly and will mark a great step towards commercialization for batteries intended for electric vehicles.

Expansion of NanoGraf, including new facilities in Chicago, seems to be moving in the direction of meeting military and commercial markets’ requirements, thereby bringing the silicon-graphene technology down to a lower cost and perhaps an even wider market.

Conclusion: A Potential Game-Changer?

The military is interested in SOG batteries due to the more advanced energy solutions required to fulfill modern, tech-heavy missions. Silicon graphene technology doesn’t just solve military-specific problems but can be a game-changer for the overall landscape of energy storage for everyday consumers. As the innovation journey continues and large-scale production roads become clearer, silicon-graphene batteries may soon power devices beyond the battlefield, opening a new frontier in battery technology.”.