How to Grow Millions of Cucumbers in a Greenhouse: A Look at Modern Agriculture Technology

In today’s modern agriculture landscape, greenhouses are essential for efficient and large-scale production. In this article, we’ll explore the fascinating process of growing millions of cucumbers in a greenhouse using cutting-edge farming techniques like vertical farming, soilless cultivation, and advanced automation. Based on the greenhouse farming methods used in the Netherlands, one of the leaders in cucumber production, this article will break down the various stages of growing and harvesting cucumbers, from seedlings to final packaging.

1. Cucumber Farming in the Netherlands: An Overview

The Netherlands is renowned for its advanced greenhouse technology, which allows it to produce vast amounts of cucumbers year-round, despite its cold climate. In 2021, the country produced an impressive 1.2 million tons of cucumbers, making it one of the top producers in Europe. This level of production is achieved through modern methods like vertical farming and soilless cultivation, which optimize space and resources while maintaining high output levels.

2. Greenhouse Technology and Infrastructure

Modern cucumber greenhouses in the Netherlands are equipped with state-of-the-art technology to enhance productivity and ensure optimal growth conditions. These greenhouses use biological fiber mats (often made from coconut fiber) for growing cucumbers in a soilless environment. A direct water pumping system supplies nutrients directly to the roots, ensuring the plants receive everything they need for healthy growth.

To maximize efficiency, the greenhouse facilities are vast, often requiring bicycles for workers to navigate between different sections. With such large greenhouses, up to three cucumber crops can be grown per year, each consisting of hundreds of thousands of plants.

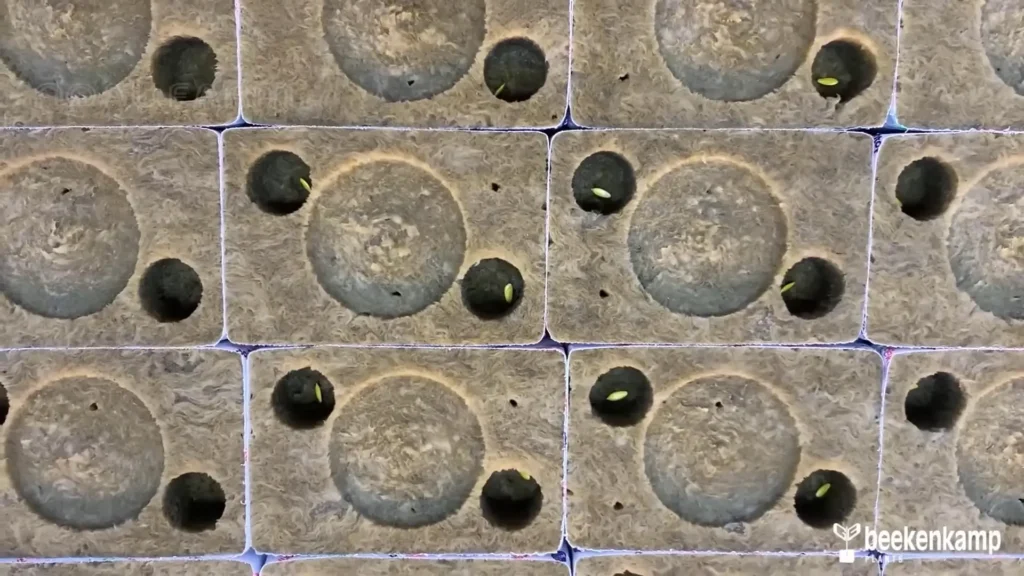

3. The Seedling Stage

The process begins with cucumber seedlings, which are grown without using soil. Instead, modern greenhouses prepare their own seedlings and support their early growth with small sticks to provide stability. After about two weeks, once the seedlings have grown strong enough, they are transplanted into the main greenhouse growing area.

4. Vertical Farming: Maximizing Space

One of the key innovations in cucumber production is vertical farming. As cucumbers are vine plants, they grow upward with the help of support systems like ropes. These ropes are secured to wires at the top of the greenhouse, allowing the cucumber plants to grow vertically. This technique not only maximizes space but also ensures that the plants receive ample sunlight and airflow, both of which are crucial for healthy growth.

To maintain proper growth, the plants are “tightened” to the ropes, meaning the ropes are periodically turned around the plants to help them grow upwards. This process continues until the plants reach the top of the crop wire. In some cases, clipping techniques are used to further support the plants, particularly in high-wire cultivation systems.

5. LED Lighting for Optimal Growth

One of the challenges of greenhouse farming in colder climates is ensuring enough light for plant growth. In the Netherlands, where winters can be long and dark, LED lighting is used to extend the amount of light the plants receive. These lights are especially important at night and have proven to be effective, allowing for up to four harvests per year from the same plants.

6. The Harvesting Process

Once the cucumbers reach the ideal size—around 35 to 40 cm in length—they are ready for harvesting. The harvesting process is done primarily by hand, using knives to cut the cucumbers from the vine. This stage requires careful attention to ensure that the cucumbers are harvested at the perfect age and color.

After harvesting, the cucumbers are immediately taken to the sorting and packaging area. Here, modern conveyor belts and robotic arms handle the sorting process, ensuring that each cucumber is graded based on size and quality. While much of the sorting is automated, human workers still play a crucial role in quality control.

7. Cleaning and Preparing for the Next Crop

At the end of the growing season, all the plants from the previous crop are removed from the greenhouse, and the space is thoroughly cleaned. This includes cleaning the roof of the greenhouse to ensure that the plants receive optimal sunlight for the next crop. After cleaning, new cucumber seedlings are planted almost immediately, ensuring continuous production throughout the year.

8. Global Cucumber Production

Cucumbers are one of the most widely consumed fruits around the world. In 2020, global cucumber production was estimated at 91.3 million tons. China is by far the largest producer, accounting for 79% of the world’s total cucumber production. The Netherlands ranks as the fourth-largest cucumber producer in Europe, following Spain, Turkey, and Poland.

Conclusion

The process of growing cucumbers in modern greenhouses, particularly in advanced agricultural regions like the Netherlands, demonstrates the power of technology in boosting food production. With vertical farming, soilless cultivation, advanced lighting, and automation, cucumber growers can produce millions of cucumbers each year, ensuring a steady supply to meet global demand.

By integrating smart farming techniques, these greenhouses not only increase productivity but also ensure the sustainability of their operations. As the world’s population continues to grow, these methods may become more crucial in ensuring food security on a global scale.

For more insights on modern farming techniques, be sure to explore other articles and videos on advanced agricultural technology!