The Rise of Cadmium Telluride (CdTe) Solar Panels: The Next Big Thing in Solar Technology

In the renewable energy world, solar panels have become a key player, with silicon-based panels dominating the market for decades. However, another type of solar panel technology is quietly making waves: cadmium telluride (CdTe) solar panels. While not as well-known, CdTe panels offer unique advantages that may soon challenge the silicon solar monopoly. In this article, we’ll explore why CdTe panels might be the future of solar power, how they work, and the challenges they face.

What Are Cadmium Telluride (CdTe) Solar Panels?

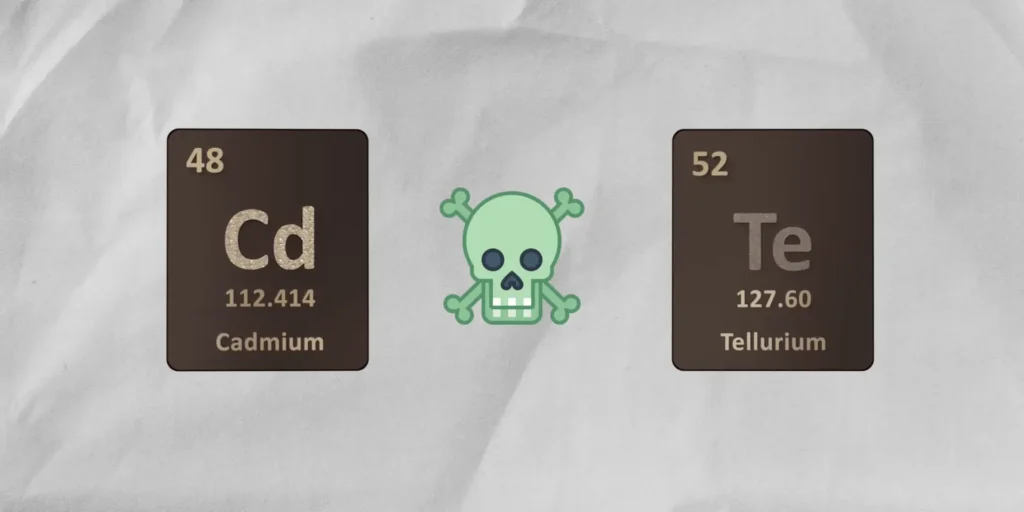

CdTe solar panels are made from cadmium and tellurium, both of which are toxic in isolation but safe when combined into a semiconductor. This combination results in a material that is highly effective at converting sunlight into electricity, making CdTe panels a strong contender in the solar industry.

While silicon still commands most of the market, CdTe technology is not new. CdTe panels are, in fact, the second-most common photovoltaic (PV) technology, used mainly in the U.S. market. These panels offer distinct advantages over traditional silicon panels, such as higher efficiency in specific situations and a thinner, more cost-effective design.

Key Advantages of CdTe Solar Panels

1. Higher Energy Efficiency

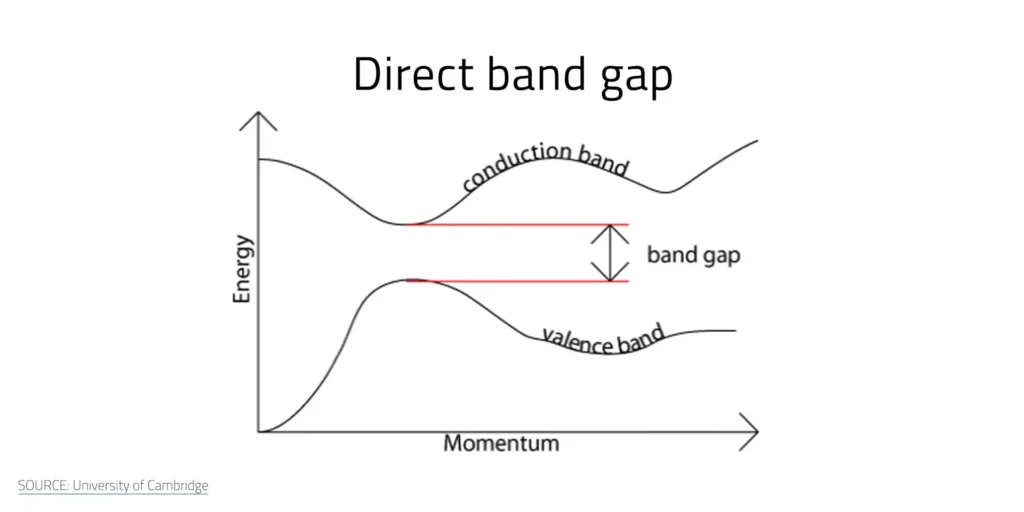

One of CdTe’s most appealing features is its energy efficiency. The material has a band gap of 1.5 electron volts (eV), which is ideal for solar energy absorption. While silicon has a band gap of 1.1 eV, CdTe’s slightly higher value allows it to absorb higher-energy photons more efficiently without overheating. This results in better performance in higher temperatures, making CdTe panels particularly well-suited for hot, sunny climates.

Additionally, CdTe is a “direct gap” semiconductor, meaning it absorbs sunlight more efficiently than silicon. As a result, CdTe panels can be much thinner and still generate comparable power levels, which reduces production costs and material usage.

2. Improved Thin-Film Technology

CdTe panels shine in the thin-film solar category, where they outclass silicon in efficiency. While traditional silicon panels see a drop in efficiency when made thinner (sometimes to as low as 6%), CdTe panels retain their efficiency even when slimmed down. This makes CdTe panels a fantastic choice for projects where weight and material costs are critical factors.

3. Durability and Longevity

CdTe panels are also known for their durability. First Solar, a major CdTe panel manufacturer, claims their panels maintain 89% of their efficiency after 30 years. This is crucial for long-term solar installations where durability and low maintenance are key priorities.

Challenges Facing CdTe Solar Panels

Despite these advantages, CdTe panels are not without their challenges. These challenges have limited their market share, which globally remains at only 4%.

1. Tellurium Scarcity

One of the major hurdles CdTe technology faces is the scarcity of tellurium, a key element in their production. Tellurium is rare—about as common as platinum—and is primarily a byproduct of copper mining. While this hasn’t made CdTe panels prohibitively expensive, it does raise concerns about scalability, especially as the demand for solar energy grows.

2. Toxicity Concerns and Recycling

Both cadmium and tellurium are toxic, which makes the recycling and end-of-life management of CdTe panels a significant issue. Fortunately, companies like First Solar have developed closed-loop recycling systems that recover more than 90% of the materials used in their panels. However, recycling at scale remains a challenge, and the environmental impact of mass-producing CdTe panels could limit their widespread adoption if not managed properly.

3. Copper Doping and Degradation

CdTe’s efficiency is often enhanced by doping with copper or arsenic. However, over time, the copper can degrade the material’s lattice structure, reducing the panel’s efficiency. This issue has been partly addressed with a process called copper reduction, but it remains a key area of research to ensure long-term stability.

Competing Technologies: Silicon and Perovskites

While CdTe panels have clear advantages, they are not without competition. Silicon panels remain the gold standard, with a well-established production infrastructure and efficiencies between 20% and 24%. Additionally, perovskite solar cells, though still in the research phase, offer potential efficiencies of 26.7%. However, perovskites are prone to degradation and are not yet commercially viable, leaving CdTe as a promising alternative in the short to medium term.

The Role of First Solar and Future Outlook

First Solar, the leading CdTe panel manufacturer, has played a crucial role in advancing CdTe technology. With commercial panel efficiencies of 19.3% and laboratory efficiencies reaching 23.1%, First Solar continues to push the boundaries of CdTe performance. The company aims to reach 25% efficiency by 2025, and they’re working on innovations to further boost CdTe’s competitiveness.

First Solar is also addressing environmental concerns by reducing the carbon and water footprint of their panels, making CdTe panels some of the fastest in terms of energy payback time—the period needed for the panels to “pay for themselves” in energy savings.

The Future of CdTe Solar Technology

CdTe solar technology has the potential to disrupt the solar industry, particularly in large-scale solar farms and projects where material costs and durability are critical. While it still plays second fiddle to silicon, with ongoing research and improvements, CdTe may become a more prominent player, especially as companies like Advanced Solar Power in China are ramping up production.

The path forward for CdTe includes boosting efficiency, solving degradation issues, and expanding recycling efforts. With a theoretical efficiency ceiling of 35.79%, there’s still a lot of untapped potential in CdTe technology. If these advancements are realized, CdTe could challenge silicon’s dominance and become the preferred technology for specific applications.

Conclusion

While silicon remains the dominant force in the solar panel industry, CdTe is quickly emerging as a viable alternative, particularly for large-scale solar projects. Its durability, thin-film technology, and efficiency make it an attractive option. However, challenges such as tellurium scarcity and toxicity concerns must be addressed before CdTe can overtake silicon on a larger scale.

In the meantime, as researchers continue to push CdTe’s efficiency limits and companies expand production, this “underrated indie band” of solar technology is poised to become a key player in the global shift toward renewable energy.